Impulse Hammer

Impact Hammer - Modal Hammer

Impulse hammers are designed for frequency measurement of mechanical structures, such as mechanical flexibility, mechanical damping and impedance.

IH series impulse hammers are powered by an IEPE source, an integrated force transducer is supplied with different hammer tips for different force and frequency ranges.

Impulse Hammer Price - Impact Hammer Price - Modal Hammer Price

Model: | IH -01 -1 | IH -01 | IH -02 | IH -05 | IH -10 | IH -20 | IH -50 |

|---|---|---|---|---|---|---|---|

Sensitivity mV/N | 100 | 25 | 2.5 | 1 | 0.5 | 0.25 | 0.1 |

Measuring Range N | 50 | 200 | 2000 | 5000 | 10000 | 20000 | 50000 |

Nonlinearity % | ≤ 1 | ≤ 1 | ≤ 1 | ≤ 1 | ≤ 1 | ≤ 1 | ≤ 1 |

Resolution mN rms | 2 | 6 | 50 | 100 | 250 | 450 | 1000 |

Resonant Frequency kHz | 70 | 60 | 55 | 55 | 45 | 45 | 45 |

Low Frequency Hz | 1 | 1 | 1 | 0.5 | 0.5 | 0.5 | 0.5 |

Head Weight g | 15 | 28 | 80 | 120 | 445 | 445 | 1000 |

Head Diameter mm | Φ14 | Φ18 | Φ16 | Φ20 | Φ32 | Φ32 | Φ51 |

Hammer Length mm | 125 | 250 | 250 | 250 | 340 | 340 | 400 |

Output Connector | µDOT | BNC | BNC | BNC | BNC | BNC | BNC |

Price | 977 € | 999 € | 1085 € | 1230 € | 1230 € | 1270 € | 1320 € |

IH-02

-

Price: 1225 €

Shipping price included

Model: | IH -02 |

|---|---|

Sensitivity mV/N | 2.5 |

Measuring Range N | 2000 |

Nonlinearity % | ≤ 1 |

Resolution mN rms | 50 |

Resonant Frequency kHz | 55 |

Low Frequency Hz | 1 |

Head Weight g | 80 |

Head Diameter mm | Φ16 |

Hammer Length mm | 250 |

Output Connector | BNC |

Scope of delivery:

- Impact tips: Stainless steel, rubber, nylon, aluminum

- BNC-BNC sensor cable 2 meters

- Calibration sheet

- Carrying case

Impact Hammer Test Measurement

The NVH-Imp modal test software offers all functions for experimental modal analysis.

The YouTube presentation shows you how to work with a impact hammer and an vibration sensor.

It is realized with a two-channel measurement data acquisition.

Structure Amimation Presentation

Our modal testing software supports measurement data acquisition from various manufacturers with up to 16 channels.

Here we offer you a complete impulse hammer test set at a particularly attractive price.

Select the right impulse hammer for your application from the table below.

IH-01-1

-

Price: 1117 €

Shipping price included

- Integrated preamplifier for IEPE sensor supply 2..20mA

- Stainless steel hammer head & measuring cell

- 3 different impact buffers for a wide frequency range

- Easy to operate

- robust construction

- Sensitivity 100 mV/N

- Maximum force 50 N

- Voltage range + -5V

- Frequency range from 1 Hz

- Head weight 15 g

- Length 125 mm

- Hammer head diameter 14 mm

- Aluminum handle with armored rubber

- Different impact tips for a wide frequency range

- Easy to use

- Robust construction

Scope of delivery:

- Impact tips: Stainless steel, nylon, aluminum

- 10-32-BNC sensor cable 2 meters

- Calibration sheet

- Carrying case

-

Price: 1370 €

Shipping price included

IH-05

Model: | IH-05 |

|---|---|

Sensitivity mV/N | 1 |

Measuring Range N | 5000 |

Nonlinearity % | ≤ 1 |

Resolution mN rms | 50 |

Resonant Frequency kHz | 55 |

Low Frequency Hz | 1 |

Head Weight g | 80 |

Head Diameter mm | Φ16 |

Hammer Length mm | 250 |

Output Connector | BNC |

Scope of delivery:

- Impact tips: Stainless steel, rubber, nylon, aluminum

- BNC-BNC sensor cable 2 meters

- Calibration sheet

- Carrying case

IH-50

-

Price: 1460 €

Shipping price included

Scope of delivery:

- Impact tips: White-Hard, Black-Medium, Green-Soft

- BNC-BNC sensor cable 2 meters

- Calibration sheet

- Carrying case

- Integrated preamplifier for IEPE sensor supply 2..20mA

- Stainless steel hammer head & measuring cell

- 3 different impact buffers for a wide frequency range

- Easy to operate

- robust construction

- Sensitivity 0.1 mV/N

- Maximum force 50000 N

- Voltage range + -5V

- Frequency range from 0.5 Hz

- Head weight 1000 g

- Additional mass 500 g

- Length 400 mm

- Hammer head diameter 51 mm

- Aluminum handle with armoured rubber

Modal hammer for heavy objects

-

Price: 3350 €

Shipping price included

IH-100

Model: | IH -100 |

|---|---|

Sensitivity mV/N | 0.05 |

Measuring Range N | 100 000 |

Nonlinearity % | ≤ 1 |

Resolution mN rms | 5000 |

Resonant Frequency kHz | 25 |

Low Frequency Hz | 0.3 |

IEPE Voltage | 18 – 30 Volt |

IEPE Current | 2 – 20 mA |

Head Weight g | 6100 |

Hammer Mass g | 8100 |

Head Diameter mm | Φ80 |

Hammer Length mm | 1000 |

Output Connector | BNC |

Scope of delivery:

- Impact tips: Hard – Medium – Soft

- BNC-BNC sensor cable 2 meters

- Calibration sheet

Technical

What do I have to consider in order to perform a correct EXCITATION?

For a correct excitation, the following must be ensured:

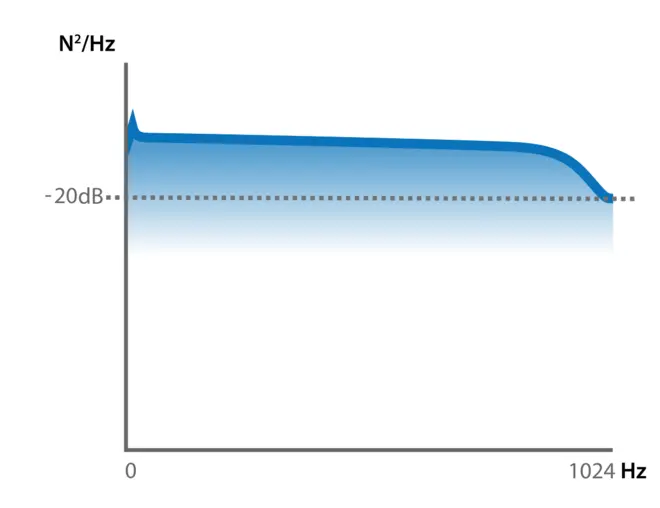

Excite the frequency range of interest with high amplitude (above the background noise of the sensor)

An amplitude uniformly distributed over the frequency range to be examined

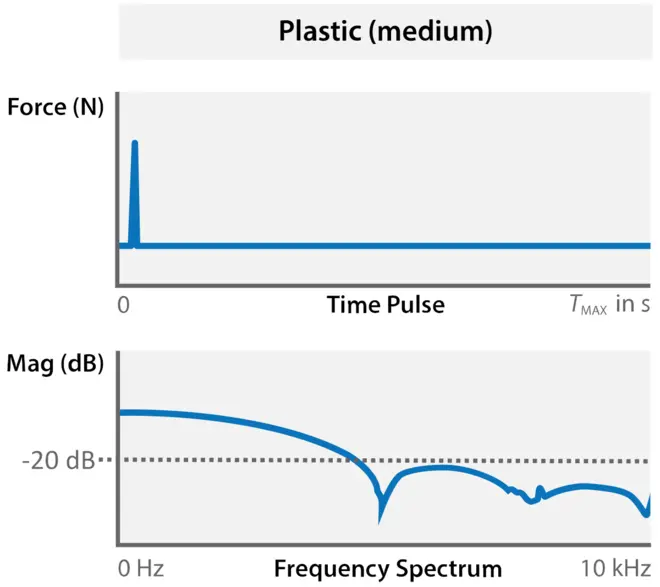

Enough energy must be generated to excite the entire frequency range of interest, but not significantly beyond. The force must not drop more than 20 dB in the excited frequency range to get a sufficient energy input.

It must be ensured that enough force is induced into the structure to excite the modes of the structures.

A correct excitation should have the following course over the frequency range to be examined:

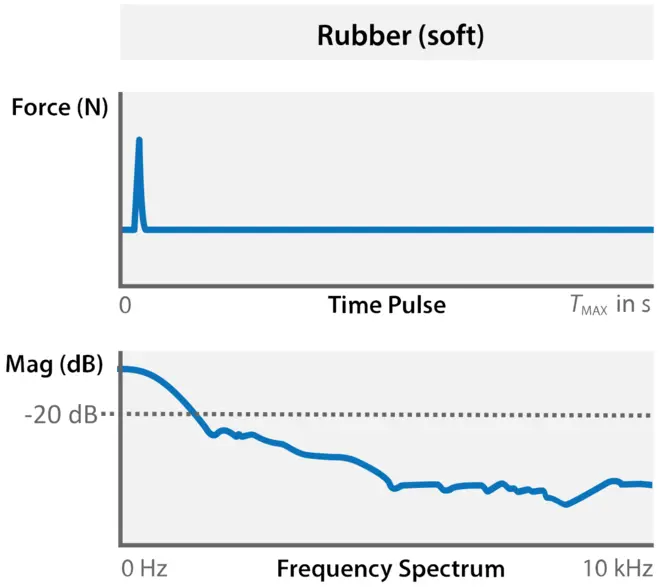

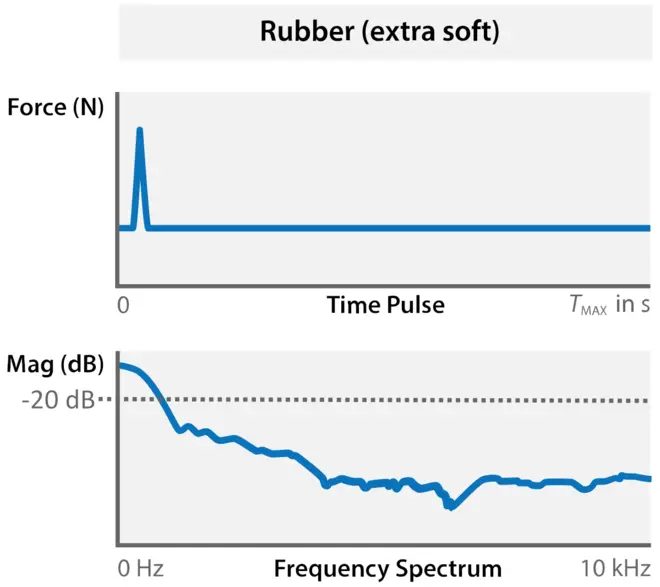

When do I use which hammer tip for excitation?

The general idea is that resonant frequencies can be more easily identified by applying the same force level over the entire frequency range.

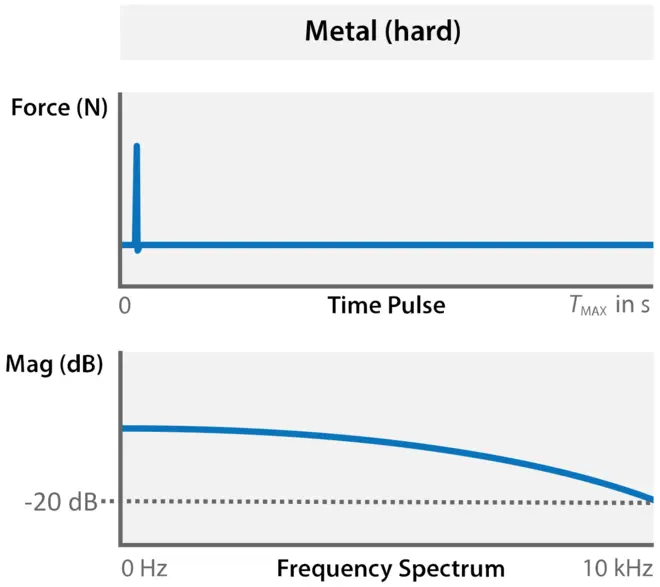

The width of the input force is controlled by the duration of the shock pulse. However, the shorter the duration of the impulse, the wider the frequency range response.

To controll the input force frequency range, you can change the hammer tip in two ways:

Hammer mass – Reducing the mass of the hammer tip causes the hammer to touch the structure for a shorter time. Because the reduced mass allows the hammer to reverse direction more easily after hitting the structure, thus reducing the contact time.

Hammer tip stiffness – Increasing the stiffness of the tip also allows the hammer to shorten the time of contact. For example, a rubber tip could be replaced with a metal tip.

A hard tip has a very short pulse and excites a wide range of frequencies. Whereas a soft tip has a long pulse and excites a narrow frequency range. But the hammer tip itself does not completely determine the excited frequency range. The local flexibility of the structure must also be taken into account.

Generally applies: The lighter the hammer and the stiffer the tip, the higher the excited frequency range.

Choice of tips:

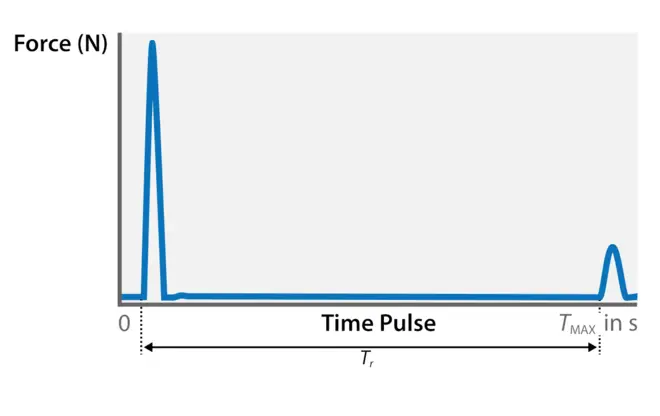

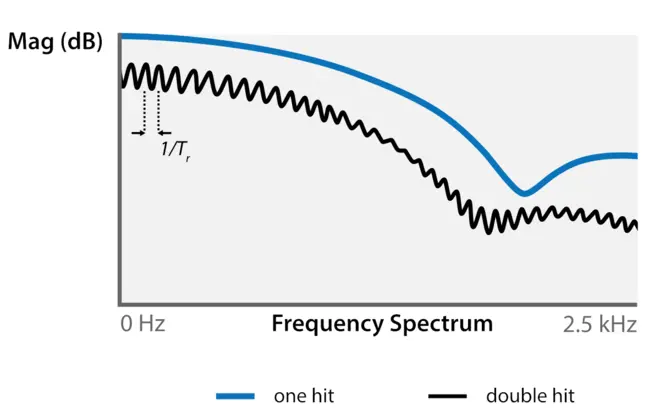

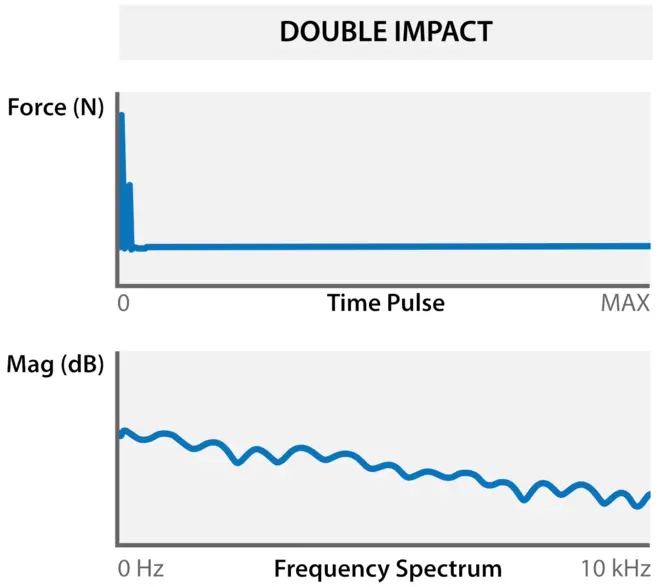

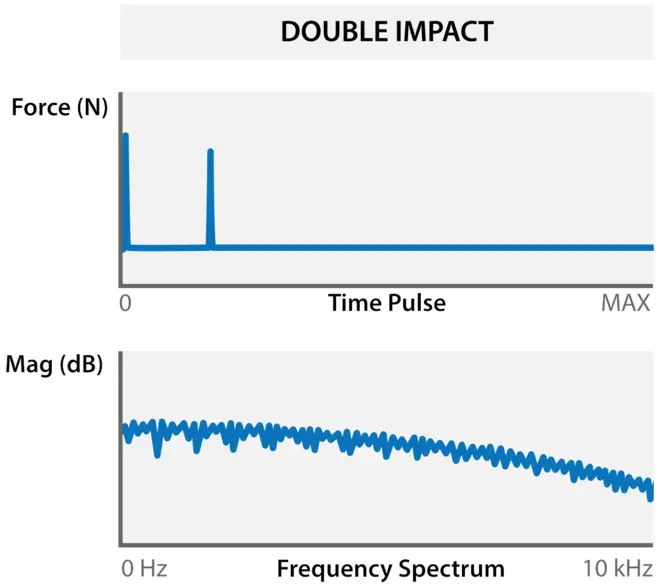

How do I recognize a doublel-hit excitation?

A double hit excitation can often be detected in the time domain as well as in the frequency domain.

If a second peak occurs in the time domain, this is an obvious evidence for a double hit excitation.

If this is not the case, it is possible that the second peak is just too small or too close to the first peak. In this case, the double hit excitation can be detected in the frequency domain.

It shows one of the following significant forms:

What is the effect of a double-hit excitation on the frequency spectrum?

The effect of the double excitation can be calculated from the time interval between the two impacts.

The following chart shows how the inverse of the time interval affects the interference in the frequency band.