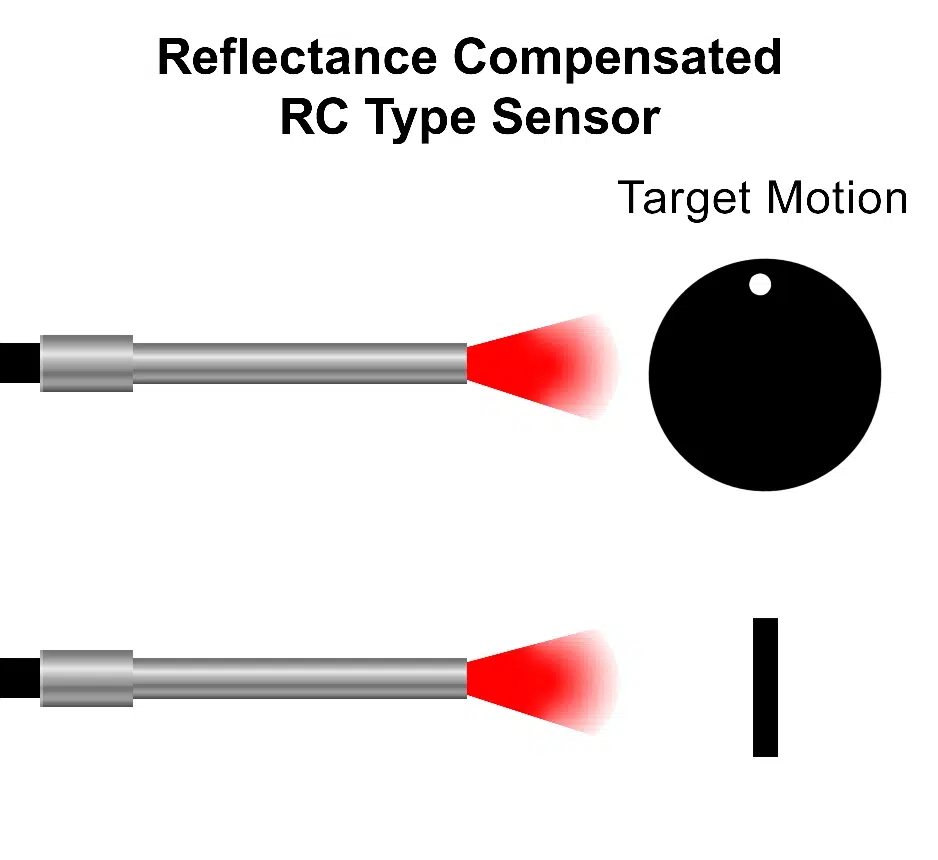

RC models are suitable for both single-axis measurements and measurements on objects that move past the sensor

- Automatic parts inspection

- Bearing / shaft dynamic measurement

- Commutator profile

- Computer hard disk mounting

- Deformation study

- Distance to glass

- Distance to paper

- Distance to plastic

- Dynamic expansion

- Waver alignment

- Process control

- Out of roundness

- Shaft orbit

- Detection for structural deformationg

- Measuring the surface quality

- Elongation and vibration of the turbine blade

- Ultrasonic vibration

- Application in ultra-high vacuum

- Vibration analysis

- Structure twist

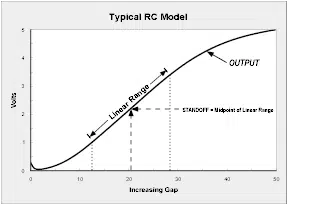

RC sensors have a positive slope with increasing displacement. In contrast to the D models, they are monovalent with no near/far optics peak range and do not have to be calibrated to the target surface.

These sensors are suitable for measuring applications with static, moving or rotating objects to be measured, e.g. B. discs and shafts, or for the measurement of parts during the process.

DC-20KHz is standard

DC-200KHz or higher is optional

DC-100 Hz provides the best resolution

Standard analog sensor units include:

Electronics with 0 to +5 VDC output

1 meter long fiber optic cable

Distance Sensors Reflection Compensated

Analog sensors are fast responding units ideal for relative motion measurements in dynamic applications with speeds up to 1 MHz.

Model | Tip Diameter | Total Operating Range | Standoff | Linear Range | Resolution 100 Hz | Resolution 20 kHz (standard) | Resolution 200 kHz |

|---|---|---|---|---|---|---|---|

mm | mm | mm | mm | µm | µm | µm | |

RC19 | 0.81 | 0.76 | 0.36 | 0.23 | 0.15 | 0.3 | 0.6 |

RC20 | 0.81 | 1.65 | 1.0 | 0.6 | 0.25 | 0.5 | 1.0 |

RC25 | 4.75 | 0.76 | 0.3 | 0.18 | 0.05 | 0.3 | 0.6 |

RC32 | 1.27 | 2.0 | 1.0 | 0.75 | 0.25 | 1.0 | 2.0 |

RC60 | 1.83 | 3.2 | 1.4 | 1.0 | 0.6 | 1.8 | 3.6 |

RC62 | 4.75 | 2.0 | 1.0 | 0.75 | 0.25 | 1.0 | 2.0 |

RC63 | 4.75 | 4.0 | 1.4 | 1.2 | 0.7 | 2.0 | 4.0 |

RC100 | 3.18 | 5.1 | 2.2 | 2.0 | 0.75 | 3.0 | 6.0 |

RC125 | 3.96 | 9.0 | 1.5 | 4.0 | 0.6 | 4.0 | 8.0 |

RC171 | 4.75 | 12.7 | 4.4 | 3.8 | 2.5 | 5.6 | 11 |

RC225 | 7.93 | 25.4 | 13.7 | 3.4 | 3.0 | 6.7 | 13.4 |

RC290 | 7.93 | 41 | 20 | 11 | 7 | 32 | 65 |

Digital Output – Displacement Sensors

Digital sensors provide linearized distance output via RS232 or USB with 5000 S/S maximum data rates.

They provide linearized distance output and onboard calibration storage capacity for 25 calibrations.

Model | Tip Diameter | Total Range | Pk-Pk resolution ADC AVG 2 | Pk-Pk resolution ADC AVG 4096 |

|---|---|---|---|---|

mm | mm | nm | nm | |

DMS-RC19 | Ø 0.5 | 0.76 | 75 | 5 |

DMS-RC20 | Ø 0.5 | 1.65 | 80 | 5 |

DMS-RC25 | 0.64×3.2 | 0.76 | 5.0 | 2.5 |

DMS-RC32 | Ø 0.8 | 2 | 75 | 10 |

DMS-RC60 | Ø 1.5 | 4 | 180 | 15 |

DMS-RC62 | 1.6×3.2 | 2 | 250 | 15 |

DMS-RC63 | 1.6×3.2 | 4 | 650 | 25 |

DMS-RC90 | 2.3×4.8 | 9 | 400 | 75 |

DMS-RC100 | Ø 2.5 | 5.1 | 600 | 100 |

DMS-RC125 | Ø 3.18 | 9 | 2500 | 250 |

DMS-RC171 | Ø 4.3 | 12.7 | 2000 | 50 |

DMS-RC225 | Ø 5.72 | 20 | 50000 | 400 |

DMS-RC290 | Ø 7.4 | 34 | 4000 | 400 |