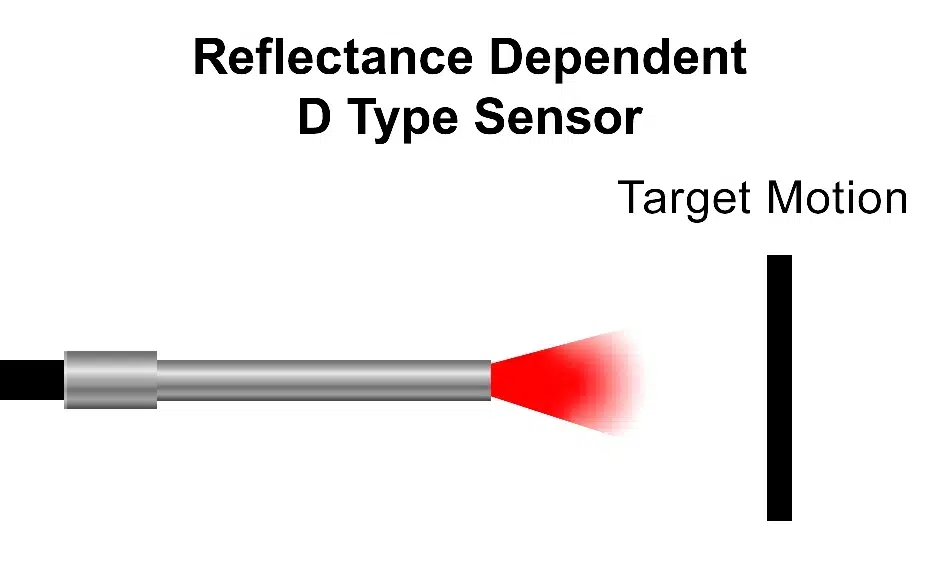

D-models are typically used for measurements on objects moving parallel to the axis of the sensor.

For applications in which the measurement object moves along the sensor axis.

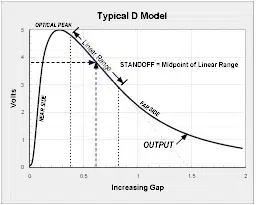

D sensors provide an output signal that is proportional to the distance and reflectance of the object surface. The output function provides two usable operating ranges: In near side operation, the highest resolution is achieved, while at far side the distances high sensitivity is available in a larger working range.

Areas of application for D sensors are, for example:

- Motion detection of the actuators

- Vibration in the ball bearing

- Deflection of the membrane

- Distance measurement in liquid

- Dynamic inspection on the fuel injector

- Penetration study and stroke study

- Positioning of parts

- Vibration investigation on the piezocrystal

- Piston Position Detection (TDC)

- Piston travel

- Detecting scratches

- Servo control

- Coil deflection

- Speed measurement

- Measuring the vibration in the ultrasonic range

- Control of the process in a vacuum

- Valve characteristic and valve lift measurement

- Automatic parts inspection

- Computer hard disk mounting

- Deformation study

- Distance to glass

- Distance to paper

- Distance to plastic

- Dynamic expansion

D-type sensors are fast-acting sensors that are ideal for dynamic applications with uniaxial movement, such as those found in actuators, pistons, and valves.

DC-20KHz is standard

DC-200KHz or higher is optional

DC-100 Hz provides the best resolution

Standard analog sensor units include:

Electronics with 0 to +5 VDC output

1 meter long fiber optic cable

The output voltage function for D-model sensors includes a near range where the voltage increases with distance, an optical peak range, and a far range where the output voltage decreases with distance.

Operation at close range results in high sensitivity with a limited measuring range. Long-range operation gives moderate sensitivity with a larger measurement range.

Distance Sensors Dependent on reflection

Model | Tip Diameter | Total Range | Near Side Range | Near Side Resolution at 100Hz | Far Side Range | Far Side Resolution at 100Hz |

|---|---|---|---|---|---|---|

mm | mm | mm | µm | mm | µm | |

D6 | 0.56 | 1 | 0.2 | 0.080 | 0.8 | 0.15 |

D12 | 0.56 | 2 | 0.25 | 0.008 | 1.75 | 0.10 |

D20 | 0.81 | 1.3 | 0.12 | 0.008 | 1.15 | 0.04 |

D21 | 0.81 | 2 | 0.25 | 0.015 | 1.75 | 0.15 |

D47 | 1.61 | 5 | 0.3 | 0.010 | 4.7 | 0.10 |

D63 | 3.18 | 3 | 0.15 | 0.002 | 2.85 | 0.13 |

D64 | 3.18 | 6 | 0.25 | 0.008 | 5.8 | 0.13 |

D100 | 3.18 | 10 | 0.4 | 0.013 | 9.6 | 0.2 |

D125 | 3.96 | 15 | 0.4 | 0.002 | 14.6 | 0.13 |

D169 | 4.76 | 20 | 0.5 | 0.008 | 19.5 | 1.25 |

D170 | 4.76 | 30 | 0.9 | 0.008 | 29.1 | 0.6 |

D171 | 4.76 | 50 | 9.5 | 0.13 | 40.5 | 0.6 |

D240 | 7.92 | 76 | 14 | 0.5 | 62 | 1 |

Displacement Sensors Reflection Dependent - Digital

Model | Tip Diameter | Total Range | Near Side Range | Near Side Resolution at ADC AVG 4096 | Far Side Range | Far Side Resolution ADC AVG 4096 |

|---|---|---|---|---|---|---|

mm | mm | mm | nm | mm | nm | |

DMS-D6 | 0.56 | 1 | 0.25 | 5 | 1 | 35 |

DMS-D12 | 0.56 | 2 | 0.25 | 2.5 | 1.75 | 15 |

DMS-D20 | 0.81 | 1.3 | 0.12 | 2.5 | 1.15 | 8 |

DMS-D21 | 0.81 | 2 | 0.25 | 2.5 | 1.75 | 15 |

DMS-D47 | 1.61 | 5 | 0.3 | 2.5 | 4.7 | 40 |

DMS-D63 | 3.18 | 3 | 0.15 | 0.5 | 2.85 | 10 |

DMS-D64 | 3.18 | 6 | 0.25 | 0.3 | 5.8 | 15 |

DMS-D100 | 3.18 | 10 | 0.4 | 5 | 9.6 | 15 |

DMS-D125 | 3.96 | 15 | 0.4 | 1 | 14.6 | 15 |

DMS-D169 | 4.76 | 20 | 0.5 | 5 | 19.5 | 80 |

DMS-D170 | 4.76 | 30 | 0.9 | 10 | 29.1 | 130 |

DMS-D171 | 4.76 | 50 | 9.5 | 50 | 40.5 | 100 |

DMS-D240 | 7.92 | 76 | 14 | 150 | 62 | 250 |